I have this combo of mobo and CPU, and when I planned my build, I was expecting to reuse an active cooling unit I had leftover from an old LGA 1151 PC build, as my research suggested that the installation holes for the LGA 1151 used in the previous build and the LGA 1155 socket used by the X9SCM-F should be the same.

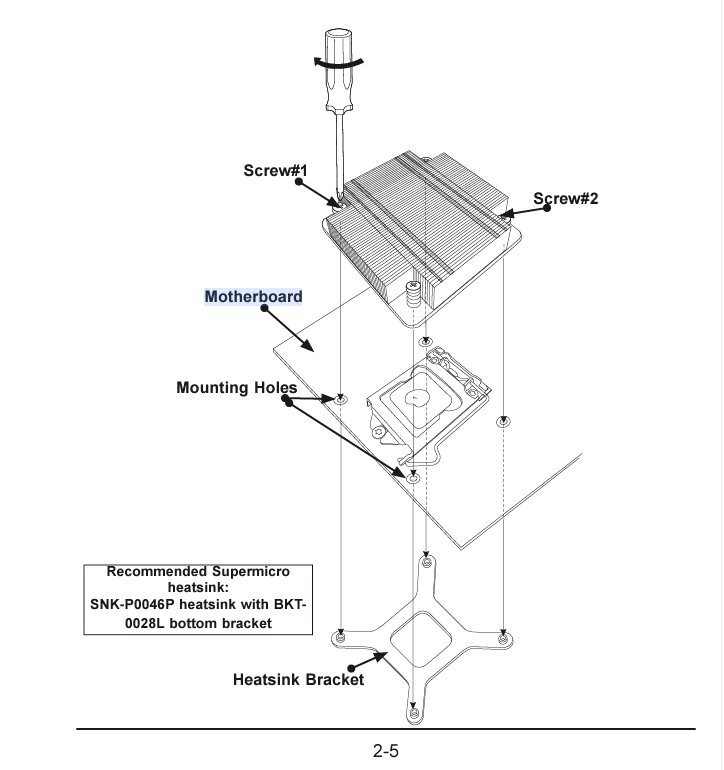

But when I received this mobo, it turned out it had been fitted with what looks like the passive heatsink pictured on page 2-5 in the mobo manual, pictured below, which includes a bracket underneath the mobo which interferes with the installation pins of the LGA 1151 active cooling unit I had. I could not figure out how to remove it, as removal seemed to require force which I'm not inclined to subject the board to:

My makeshift solution was to just strap a 80mm Arctic F8 silent 1200rpm fan I had lying about on to the passive heatsink using zip ties, to force air onto the heatsink. Sizewize, this 80mm fan is a near perfect fit onto the passive heatsink. I haven't had time to look into fan control, so I believe this fan is just running at max rpm all the time.

After finishing the build and doing some testing, it seems like the CPU is hovering around 37-45 degrees celsius under moderate load, and peaking at around 50 degrees occasionally. From my understanding, this is slightly higher than what is desirable. When peaking, I'm occasionally seing yellow and red warning signs for the CPU in the TrueNAS dashboard adjacent to the "highest usage" metric, similar to what is described here. So my question is:

Is this something I should worry about?

And if not negligible - does anyone have any good suggestion on how to improve the situation?

I found this thread which suggests that no other heatsinks exists for this mobo except the stock one, and that the passive heatsink can't be removed, which leaves me with various "creative" solutions. Would another 80mm fan with a higher rpm be my best bet? And if so, can anyone recommend a faster fan that is still somewhat silent, affordable and easy to get hold of?

Advance thanks!

But when I received this mobo, it turned out it had been fitted with what looks like the passive heatsink pictured on page 2-5 in the mobo manual, pictured below, which includes a bracket underneath the mobo which interferes with the installation pins of the LGA 1151 active cooling unit I had. I could not figure out how to remove it, as removal seemed to require force which I'm not inclined to subject the board to:

My makeshift solution was to just strap a 80mm Arctic F8 silent 1200rpm fan I had lying about on to the passive heatsink using zip ties, to force air onto the heatsink. Sizewize, this 80mm fan is a near perfect fit onto the passive heatsink. I haven't had time to look into fan control, so I believe this fan is just running at max rpm all the time.

After finishing the build and doing some testing, it seems like the CPU is hovering around 37-45 degrees celsius under moderate load, and peaking at around 50 degrees occasionally. From my understanding, this is slightly higher than what is desirable. When peaking, I'm occasionally seing yellow and red warning signs for the CPU in the TrueNAS dashboard adjacent to the "highest usage" metric, similar to what is described here. So my question is:

Is this something I should worry about?

And if not negligible - does anyone have any good suggestion on how to improve the situation?

I found this thread which suggests that no other heatsinks exists for this mobo except the stock one, and that the passive heatsink can't be removed, which leaves me with various "creative" solutions. Would another 80mm fan with a higher rpm be my best bet? And if so, can anyone recommend a faster fan that is still somewhat silent, affordable and easy to get hold of?

Advance thanks!